Conventional solar cells versus Maxeon cells: the difference will surprise you.

While we know that solar energy can be used to perform a variety of tasks for your home or office space, exactly what is happening behind the scenes of that solar panel? Essentially, solar cells produce electricity through a natural reaction called the “photoelectric effect.” What this means is light energy is converted to electric energy, which can be used to power a home or business. But not all solar cells are created equally. Conventional solar cells are fragile and susceptible to corrosion, whereas Maxeon cells are stronger, work harder, and are superior to their standard counterparts. This is all part of the SunPower Difference.

SunPower: Taking Solar Cells to the Next Level

Here’s how conventional solar cells work: most solar cells are just silicon “sandwiches,” which are specially treated to make them better electrical conductors. Individual silicon wafers used to manufacture PV cells are embedded with metallic contacts, or wires. Maxeon cells already have the average solar cell beat simply because of their structural differences; most solar cells have a metal paste or some other flimsy backing that sits on the roof or the underside of the array, which is easily cracked or damaged due to its fragility.

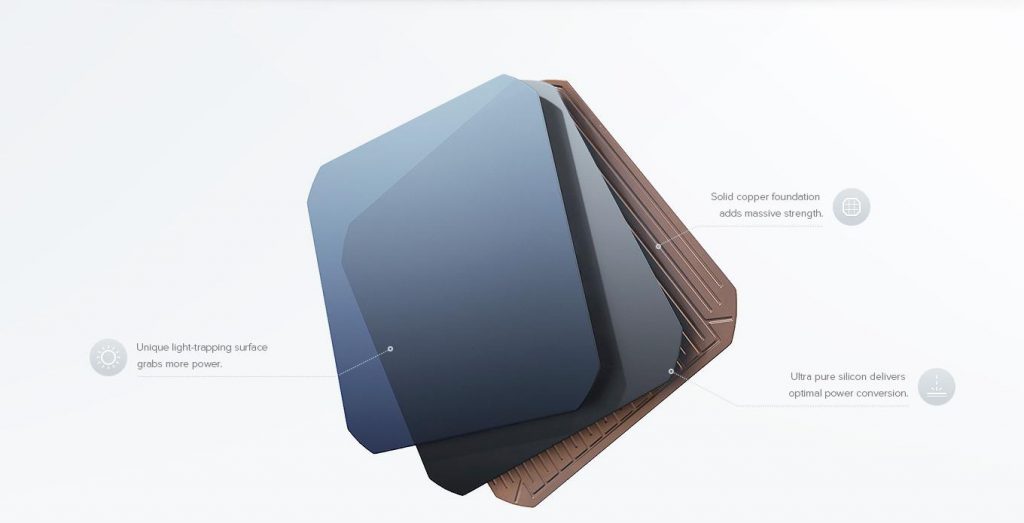

Maxeon cells are backed with solid copper, which is sturdy and resists corrosion from the elements much more than metals used in conventional solar cell design. The metallic connectors between the cells on SunPower arrays are thicker, and therefore more resilient to daily wear and tear from thermal expansion as the temperature changes.

On the front of Maxeon cells, you won’t find any of those fine lines. The lines on other arrays in the industry are also composed of metal paste, and reflect a portion of the sun’s rays back into the atmosphere, robbing them of potential efficiency gains. What this means is there are weak points that are prone to corrosion as well.

The Maxeon cell has a fundamentally different design from a Conventional Cell: it’s built on a solid copper foundation. Copper plated solar cells cost more to manufacture than Conventional Cells, but the investment pays off with a much more reliable and high-performing solar cell. SunPower starts with a tough, durable copper foundation – the Conventional Cells are made by baking a metal paste onto the silicon wafer – just like screen-printing a logo onto a T-shirt.1. SunPower Panel with Maxeon. Conventional Panel (same size) FRONT. BACK. No metal. Copper-plated. FRONT. Thin lines of metal paste. BACK. Full-coverage metal paste W. The Maxeon Solar Cell is the heart of the SunPower panel. As everyone understands, those cells produce far more energy in the same space. In the example shown here for two panels of the same size, the Gen 3 Maxeon solar cells which make up the X-Series panels are rated at 345W vs. the most common wattage rating for Conventional Panels: 250W (the average panel wattage of top conventional crystalline manufacturers from Photon and IHS). Also, the front-side is clearly different because there’s no metal grid-lines, and that provides the clean premium look associated with SunPower panels. But the increased power output and the different appearance is not the fundamental difference which justifies the high reliability value of the SunPower panels. That difference is that the Maxeon solar cells are built on a SOLID COPPER FOUNDATION. This is absolutely unique in the solar industry, and in fact it costs SunPower considerably more to build cells on a solid copper foundation – the machines that do the plating process to create this foundation are each a football field in length. The picture on the left shows the front of the Maxeon cell, with no metal at all. The interesting side is actually the back: it’s entirely covered with copper plating. That’s the foundation. In contrast, the picture on the right shows a Conventional Panel. The metal on the front and back of the cell is not really metal at all – it’s a conductive paste that’s made of tiny bits of silver and aluminum that’s baked onto the silicon wafer. In fact the process of making those cells is the same as screen-printing a design on a tee-shirt: you create a template, wipe the paint across the template and the remove the template to leave the paint where you want it on the tee-shirt, and then bake the tee-shirt to cure the paint onto the fabric. This same screen-printing process is used to apply the thin lines of metal paste on the front, and the full-coverage metal paste on the back, to create a Conventional solar cell. But unlike the strength and ductility of the solid copper foundation of the SunPower cell, the metal paste of the Conventional Cell offers NO strength to the thin silicon wafer, and as we’ll talk about soon, this fundamental design difference drives the big reliability advantages of the SunPower panels. Note that the definition of a Conventional Panel: 15.3% efficient 250W panel that’s about 1.6 square meters in area … this is the primary work-horse of the industry W. 1 Definitions used throughout presentation: Conventional Panel is a 250W panel, 15.3% efficient, approx. 1.6 m2, made with Conventional Cells. Conventional Cells are silicon cells that have many thin metal lines on the front and 2 or 3 interconnect ribbons soldered along the front and back.

Because corrosion or failure of cell interconnectors are responsible for the majority of cells that stop working, Maxeon cells are guaranteed to be in service much longer than the competition, and working more efficiently all the while. And because they are designed to produce 70% more energy than conventional cells, you’re investing in a serious — and quite literal — powerhouse that will outlast the competition.

SOURCE: BuySolarLocal.com